Laser Cable Low Power

-

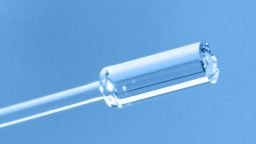

SMA-Standard

- Applfications: Laser, Sensors Spectroscopy

- Wave Length: UV-VIS-NIR

- Protective Tubing: Metal, PVC (Aramid-Strain Relief ), Silicone

-

FC/PC – FC/APC

Laser Cable Low Power FC/PC – FC/APC Execution with ZrO2 ferrules for single and multimode fibers up to 128μm cladding diameter and metal ferrules for fibers with a cladding diameter from 128μm. APC version with bevel cut of 8 °. Technical Specification Gallery Options

Laser Cable High Power SMA

-

Laser Cable High Power SMA – up to 50 W

High Power SMA laser cables – up to 50 W are available in 2 versions, which differ in the length of the connector body. This difference affects the thermal efficiency of the connector. Basically, the larger the plug, the higher the heat dissipation. At higher powers, copper ferrules are used. The complete structure is torsion- […] -

Laser Cable High Power SMA – up to 100 W

High Power SMA laser cables – up to 100 W are generally offered with a copper ferrule for freestanding fibers. This allows a very good thermal efficiency through high heat dissipation. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable. The ferrule area is guaranteed free of glue. -

Laser Cable High Power SMA – up to 500 W

High power SMA laser cables – up to 500 W are available in 2 versions, depending on the required heat dissipation: with passive or active cooling. Optional are end caps and mode stripping. Basically only with copper ferrules for freestanding fibers. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable.

Laser Cable High Power D80

-

D80 Passive Cooling

Laser cables High Power D80 Passive cooling - up to 500 W are mainly used in the area of material processing such as laser cutting or laser welding. The passive heat sink as well as 4mm copper ferrule allow a high thermal efficiency due to a very good heat dissipation. Optionally available with end caps and mode stripping. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable. -

D80 Active Cooling

Laser cables High Power D80 Active cooling - up to 1 KW are used as well as passively cooled high power connectors in the field of material processing: laser welding, laser cutting. Due to the active cooling of the connector body, however, an even higher optical power condition is possible by very efficient heat dissipation. Optional versions with mode stripping and end cap are available. The complete structure is torsion- and stress-free mounted, but mechanically extremely stable. -

D80 Fiber Monitoring

Laser cables High Power D80 fiber breakage monitoring are used in particularly critical applications, where a defect in the fiber can have particularly serious consequences. Apart from the fiber break, the plug temperature is also detected. The system shuts off automatically in the event of a defect, thus preventing uncontrolled leakage of the laser beam. Optionally, fiber breakage monitoring is also available for HP-SMA connectors.

Technology

-

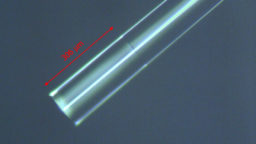

End Cap for Multimode Fibers

For small fiber core Diameters with high power density dominate fiber connectors with a cylindrical end cap made of quartz glass currently. This end cap is larger than the fiber core and is spliced to the optical fiber. In doing so, the laser beam is focused onto the fiber core via the end surface of the quartz cap, where, at the same laser power, the power density is significantly lower. -

End Cap for Singlemode Fibers

During coupling into a singlemode fiber, the laser beam is focused into the fiber core, resulting a high power density on the facet. This is higher the smaller the fiber core and larger the laser power. To reduce the power density, an end cap will be spliced on the fiber facet. The laser beam is focused on the fiber core over the end face of this end cap, where at the same laser power, the power density is significantly lower. -

Mode Stripping

The mode stripper is installed in the connector body and removes the cladding modes over a certain length. The required length is defined according to the coupling properties (spot size or NA difference). The mode stripper ensures that the beam profile at the fiber exit looks optimal. The stripped cladding modes are converted into heat in the connector body. -

Fiber Monitoring

This safety system monitors temperature and possible fiber breakage as well as connectivity. This can happen if the fiber was bent too tightly or torsedtoo much during the application or was mechanically damaged altogether.